What is LIMEXTM

Limestone is a sustainable raw material, with abundant reserves all over the world. It is 100% self-sufficient and said to be almost inexhaustible. We believe that this sustainable material can save the world.

Limestone, the raw material used in the production of LIMEX, is an abundant material with reserves all over the world. Limestone is said to be a resource with a very low risk of depletion in comparison to oil, water, and forest resources. As the UK reshapes its supply chains to create a more sustainable and circular economy, LIMEX offers an alternative to plastic packaging by creating products that contain less than 50% plastic. By decreasing the amount of petroleum-based resin used in the manufacturing process, we decrease our impact on global climate change by reducing our CO2 emissions by around 50 times.

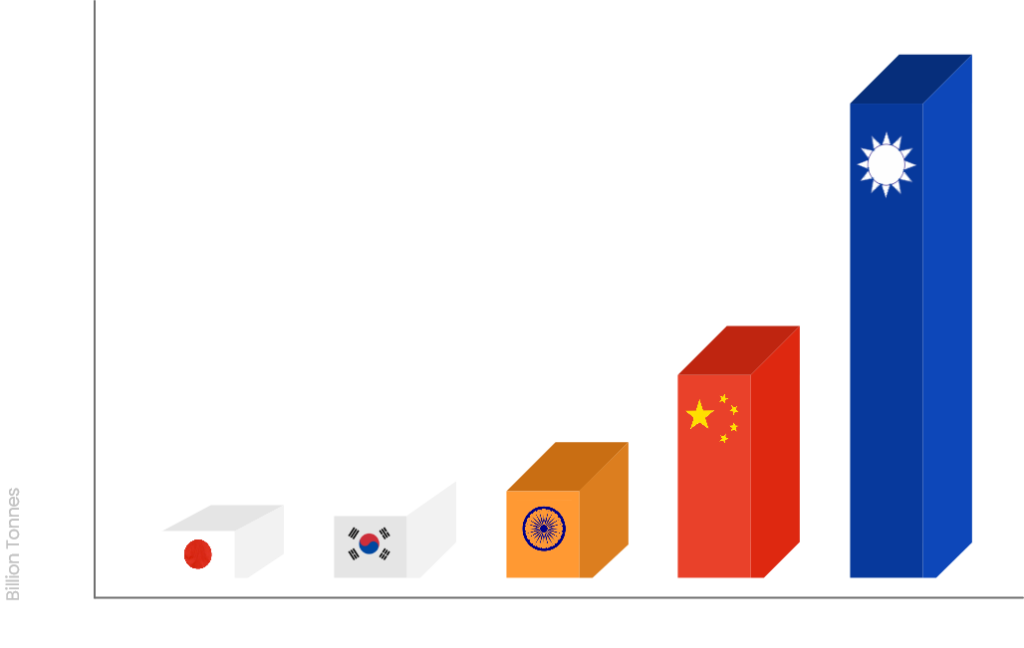

Limestone Reserve

Superiority of Limestone

In the raw material procurement process, petroleum-based resins are manufactured by fractional distillation of crude oil as well as naphtha and polymerizing the extracted monomers. The impact this method has on climate change is caused by the consumption of energy during the heating process. However, calcium carbonate, the main raw material of LIMEX, is produced by crushing limestone. This difference in processing can reduce CO2 emissions by about 50 times when compared to petroleum-based resins. In addition, the mining and processing of limestone is easier than that of petroleum and metal. The physical characteristics of limestone are more stable and therefore not as easily affected by environmental factors such as sunlight which are known to deteriorate plastics and rubbers. As it is abundant around the world, it has excellent supply stability and is inexpensive.

Co2 Emitted during Raw Material Procurement

Co2 Emitted during Combustion

Flexible Moulding Using LIMEXTM

LIMEX is suitable for diverse moulding methods including injection moulding, extrusion moulding, vacuum moulding, and blow moulding. Though LIMEX is a composite material, it does not require custom equipment and can be processed using traditional methods and machinery. LIMEX is used by more than 6,000 companies and municipalities for a variety of purposes. (As of June 2021)

LIMEXTM Manufacturing Process

LIMEX is an advanced material produced from calcium carbonate (CaCO3), which is derived from limestone, and a small amount of polymeric resin added as a binder. These materials are heated and kneaded in a twin screw extruder, creating a molten, homogeneous composite containing over 50% calcium carbonate by body weight. Next, the composite is heated and pressurized treated under LIMEX’s proprietary manufacturing process, resulting in material properties ideal for post-processing.

Pellets

LIMEX pellet is manufactured by pelletizing, the process of molding the molten composite into the shape of a pellet. LIMEX pellet is also manufactured by pelletizing edge waste produced through manufacturing and printing process or used LIMEX sheets collected from consumers. Since the amount of petroleum-based resin contained in conventional plastic products can be reduced, LIMEX is used as a material to “reduce plastic”.

Sheets

LIMEX sheet is manufactured by T-die sheet extrusion of the molten composite, and stretching process controlling a porous structure in order to create whiteness and lightness. Next, a specific coating agent is applied onto the surface of LIMEX sheet depending on its application, enhancing surface properties for various kinds of printing process. Stone paper and LIMEX Sheet are different products.

Pellets

LIMEX pellet is manufactured by pelletizing, the process of molding the molten composite into the shape of a pellet. LIMEX pellet is also manufactured by pelletizing edge waste produced through manufacturing and printing process or used LIMEX sheets collected from consumers. Since the amount of petroleum-based resin contained in conventional plastic products can be reduced, LIMEX is used as a material to “reduce plastic”.

Sheets

LIMEX sheet is manufactured by T-die sheet extrusion of the molten composite, and stretching process controlling a porous structure in order to create whiteness and lightness. Next, specific coating agent is applied onto the surface of LIMEX sheet depending on its application, enhancing surface properties for various kinds of printing process. Stone paper and LIMEX Sheet are different products.